- CNGBS B2B

- 公司介绍、新闻动态、展会活动等信息

- 工博士网

- 工博士-智能制造供应链、FA工厂自动化、MRO工业品一站式采购平台

CNGBS Robotic Intelligent Grinding Equipment is capable of performing high-speed, high-volume, and precise grinding tasks while also enhancing production efficiency and product quality. It supports a wide range of robotic intelligent equipment categories to meet different working condition requirements. Combining safety and aesthetics, it has gained extensive application in the industrial sector.

01 CNGBS Intelligent Grinding Equipment

CNGBS Robotic Intelligent Grinding Equipment is primarily used for grinding metal composite materials, such as aluminum alloy, cast aluminum, stainless steel, and carbon steel.

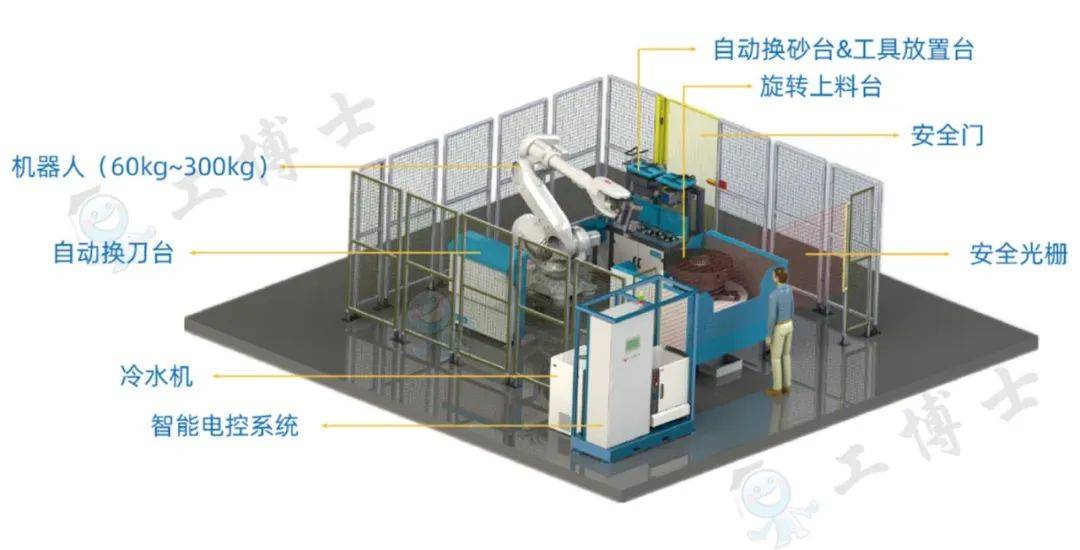

Grinding equipment must consider not only the robot body and grinding tools but also the coordination among the grinding workbench, robot control system, sensor system, robot fixture, and auxiliary equipment.

CNGBS Intelligent Grinding Equipment features professional engineers who fine-tune the configuration of each control system, allowing the grinding robot's performance to be fully utilized and achieving efficient and precise grinding work.

Workstation Types

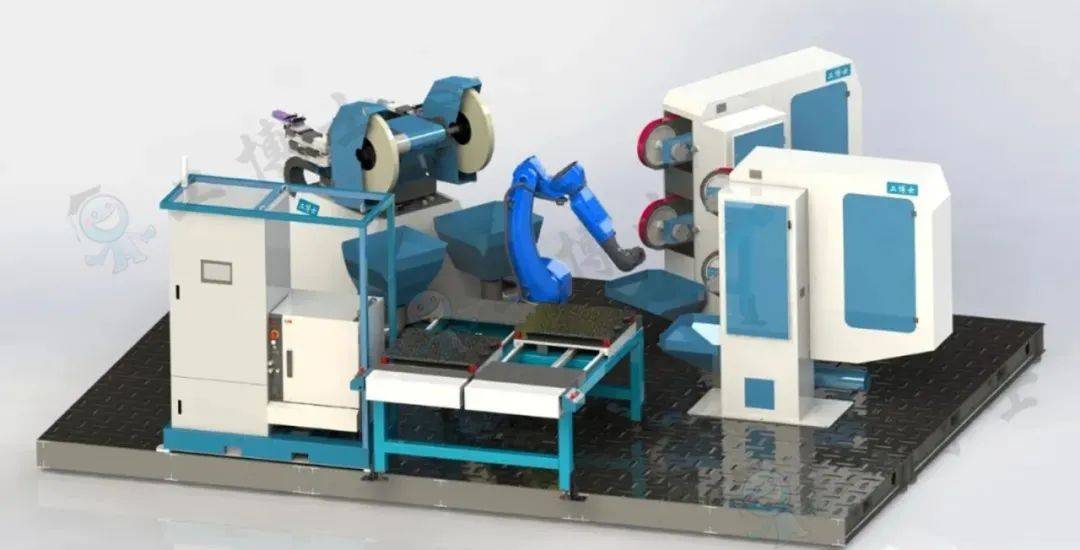

Hardware Small Parts Grinding Station

The industrial robot grinding workstation consists of an industrial robot, an electric grinding/polishing machine, a workpiece feeding table, a fixture, a dust collection device, an electrical control system, robot protective equipment, and system network interfacing.

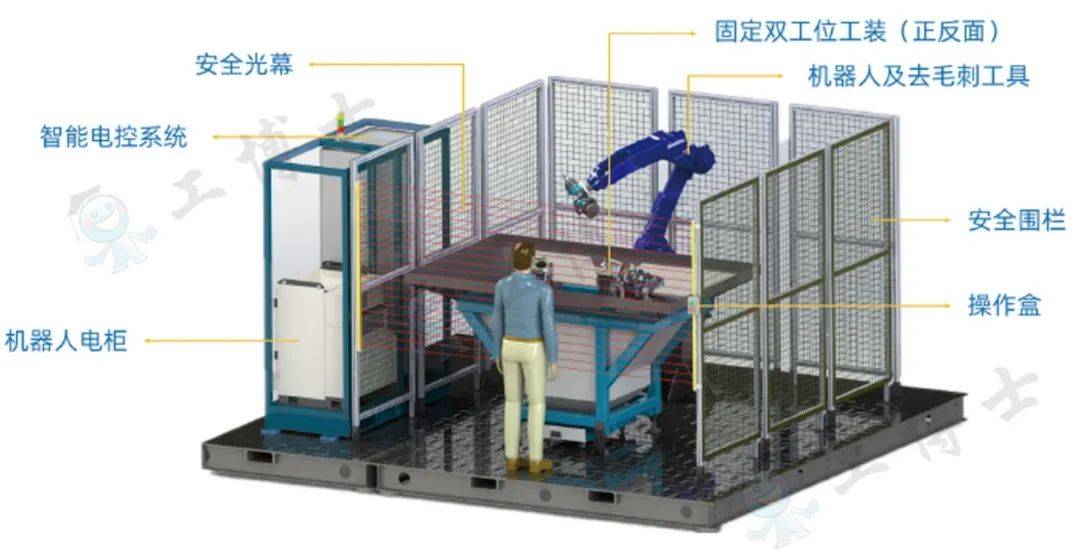

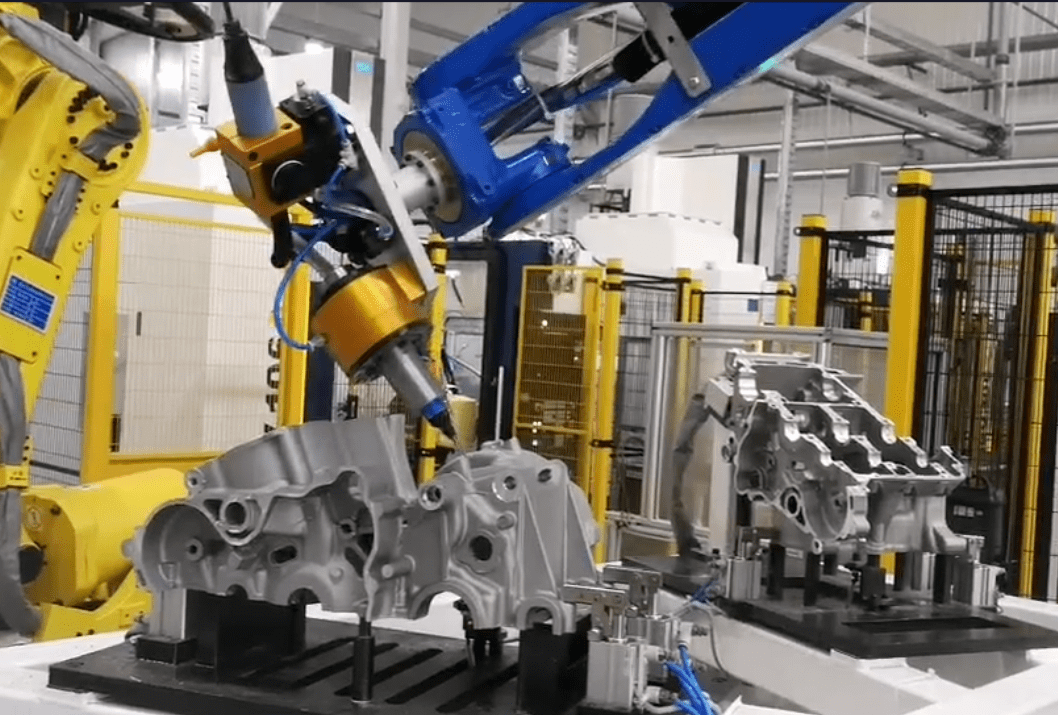

Cast Aluminum Part Deburring Station

The CNGBS Cast Aluminum Part Deburring Station adopts a single or dual-robot collaborative mode, using Yaskawa robot bodies for high processing precision. Its flexible design allows for rapid and free switching of grinding paths for hundreds of types of workpieces.

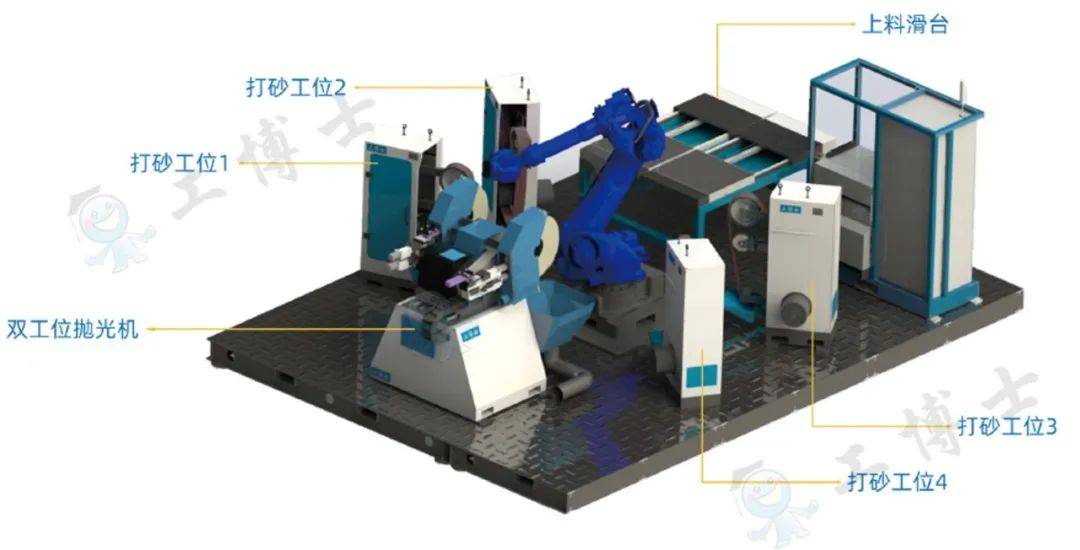

Cast Aluminum Part Deburring/Polishing Station

The CNGBS Cast Aluminum Part Deburring/Polishing Station is equipped with a full set of fixtures, can automatically adjust processing tools, performs comprehensive deburring, achieves a high degree of automation, and improves efficiency and accuracy.

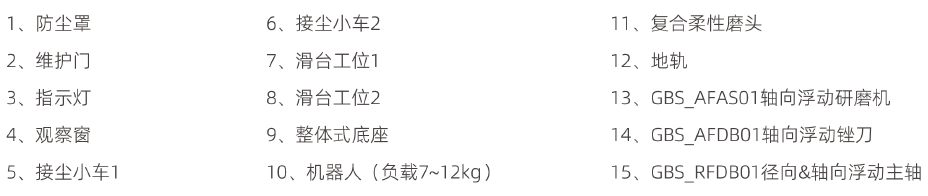

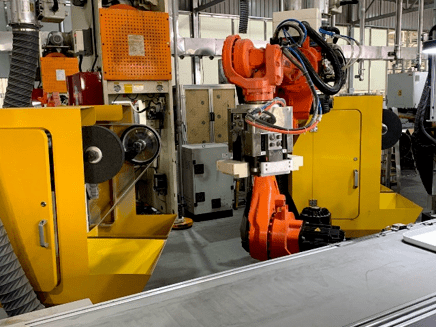

Metal Surface Treatment Comprehensive Station (Milling, Grinding)

The CNGBS Metal Surface Treatment Comprehensive Station (Milling, Grinding) is equipped with offline programming software and a complete set of fixtures. The entire machine is easy to operate and features stable performance, and can also handle processing of complex shapes and features.

Precautions

Different materials, manufacturing processes, structural forms, and规格大小 (specifications/sizes) are provided to meet customers' process requirements for workpieces.

Different robot types and project processes lead to different requirements for customizing robot fixtures and feeding tables.

Variations in materials, working conditions, etc., can directly affect the service life of the grinding workstation.

Special treatment is required for the robot installation fencing in the grinding environment.

02 Case Showcase

CNGBS Intelligent Grinding Equipment Cases

Grinding

Deburring

Grinding and Polishing

Grinding and Polishing

Inquiry Hotline

+86 021-31666777

Service Hotline

Follow us on WeChat

Scan to Follow

Scan to Follow