CNGBS предоставляет услуги по диагностике и ремонту контроллеров роботов, как аппаратных, так и программных.

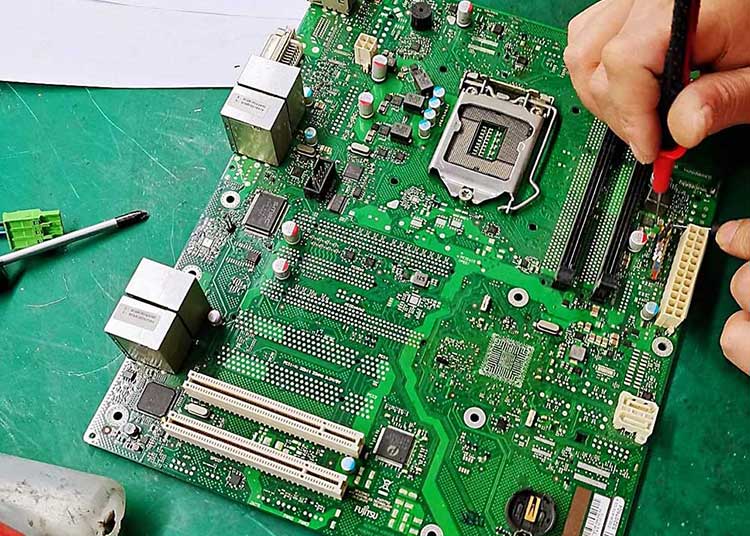

Распространенные проблемы включают повреждение печатных плат, ошибки логики программы или неисправности модулей связи, которые устраняются с помощью тестирования сигналов осциллографом, сброса прошивки или замены поврежденных компонентов.

Регулярное техническое обслуживание помогает предотвратить потенциальные отказы, такие как окисление контактов и старение конденсаторов.

Эта услуга включает в себя проверку механической конструкции, компонентов передачи и датчиков.

Типичные неисправности включают износ сочленений, перегрев двигателей или утечку масла из редукторов, которые устраняются заменой уплотнений, калибровкой передаточных отношений или очисткой энкодеров.

Мы также проводим проверки цепи аварийной остановки и системы обнаружения столкновений, а также регулярные проверки на износ кабелей.

Мы диагностируем и ремонтируем распространенные проблемы учебных пультов, включая нечувствительные сенсорные экраны, пустые дисплеи и перебои в связи.

Наши ремонтные услуги варьируются от капитального ремонта с полной заменой блока до мелкого ремонта с локальной настройкой, используя такие технические методы, как тестирование цепей, замена аппаратного обеспечения и отладка программного обеспечения.

Горячая линия для запросов

+86 021-31666777

Горячая линия обслуживания

Подпишитесь на нас в WeChat

Сканируйте, чтобы подписаться

Сканируйте, чтобы подписаться