Мы обеспечиваем безопасность во взрывоопасных средах для таких отраслей, как химическая промышленность, нефть и газ, и военная промышленность, используя методы защиты продуваемым корпусом (Ex p), взрывонепроницаемого исполнения (Ex d) и искробезопасности (Ex i).

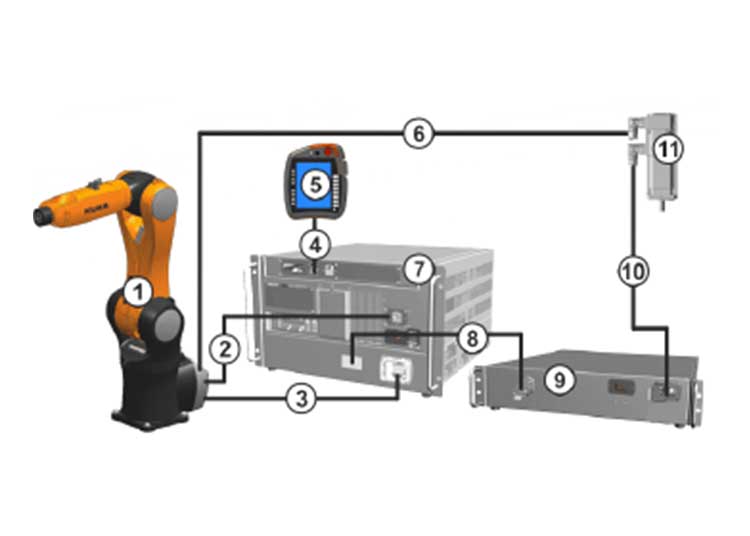

Модификации включают герметизацию корпуса робота в металлическом взрывозащищенном корпусе, интеграцию системы управления продувкой (поддержание внутреннего давления выше внешнего) и модернизацию до взрывозащищенных разъемов, датчиков и электрических шкафов.

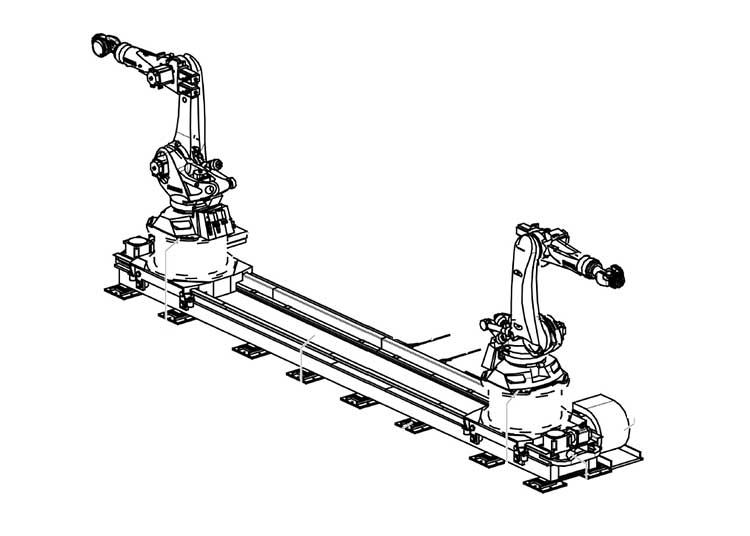

Эта услуга добавляет внешние сервооси (например, поворотные столы, позиционеры или линейные направляющие) к стандартным 6-осевым роботам, обеспечивая 7-осевое или даже многоосевое скоординированное движение.

Благодаря комплексной настройке системы (включая алгоритмы синхронного управления и интеграцию аппаратных/программных интерфейсов) мы обеспечиваем точное и скоординированное движение между добавленными осями и роботом.

Сценарии применения: Идеально подходит для процессов, требующих многоуглового позиционирования, таких как сварка и обработка крупных заготовок, значительно повышая гибкость производства.

Это включает установку мобильной каретки робота на существующую рельсовую систему, интегрированную с системой кабельных цепей для защиты силовых кабелей, воздушных линий и сигнальных кабелей.

После модернизации робот может перемещаться по направляющей для обслуживания нескольких станций, удовлетворяя пространственным требованиям, возникающим из-за изменений процесса (например, новые рабочие станции, расширенные производственные линии).

Ключевое преимущество: Избегает затрат на покупку дополнительных роботов и остается совместимым с существующей оборудованной базой.

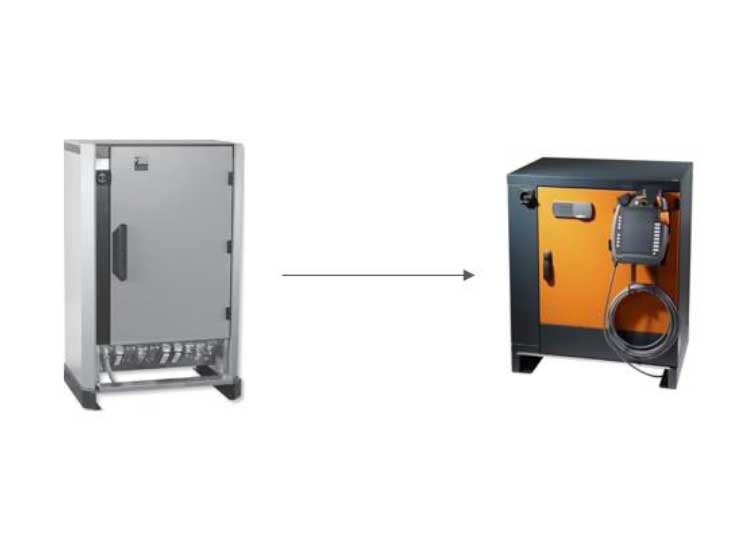

Обновляет устаревшие системы управления роботами до платформ нового поколения (например, новый контроллер, пульт обучения и программное обеспечение), обеспечивая постоянную доступность запасных частей и техническую совместимость.

Устраняет риски, связанные со старением электрических компонентов (например, отказы печатных плат, кабелей), сокращает незапланированные простои и открывает новые функциональные возможности (например, расширенное управление движением, подключение к IoT).

Экономическая выгода: Продлевает срок службы существующих роботов, предотвращая полное устаревание из-за устаревших систем.

Перепрофилирует существующие рабочие станции (например, преобразование станции точечной сварки в транспортировку материалов) путем замены конечных эффекторов (захватов, сварочных горелок и т.д.), корректировки программной логики и повторной интеграции датчиков.

Бесшовная интеграция в существующие линии: Сохраняет базовую инфраструктуру (например, ограждения безопасности, поток материалов), обновляя только основную рабочую единицу, что минимизирует время простоя при модернизации.

Полный спектр услуг, охватывающий демонтаж оборудования, транспортировку, установку на новом месте, механическую/электрическую пересборку, повторную калибровку точности и отладку программы.

Восстанавливает робота до рабочего состояния, предшествовавшего передислокации, обеспечивая соответствие точности траектории и стабильности времени цикла первоначальным стандартам. Включает необходимые обновления систем защиты (например, пакеты обслуживания кабелей/пневматики, системы заземления).

Реализует специальные протоколы защиты для точных компонентов (например, редукторов, энкодеров) для предотвращения повреждений во время перемещения.

Горячая линия для запросов

+86 021-31666777

Горячая линия обслуживания

Подпишитесь на нас в WeChat

Сканируйте, чтобы подписаться

Сканируйте, чтобы подписаться