Отдел аэрокосмической робототехники CNGBS был создан в результате сотрудничества между компанией CNGBS, бывшей технической командой CSF Asia из Австралии и исследовательскими группами отечественных университетов. Компания два года подряд (2023-2024) была удостоена звания эталонного предприятия Шанхая в области интеллектуальной робототехники за свои разработки в области «Шлифовки и полировки композитных материалов для самолетов» и «Нанесения покрытий на композитные материалы для фюзеляжа и хвостового оперения самолетов».

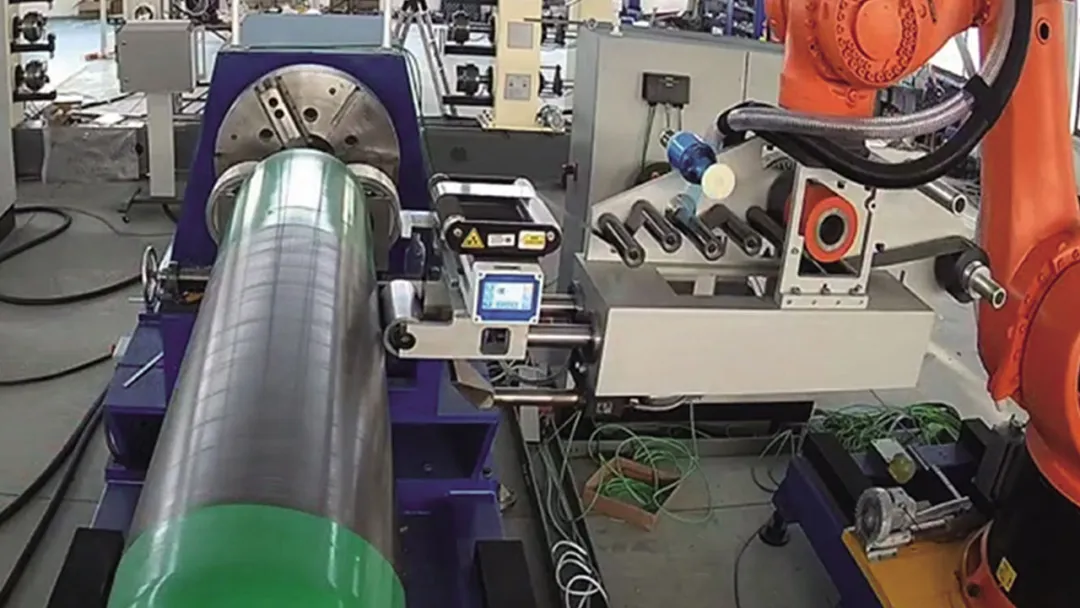

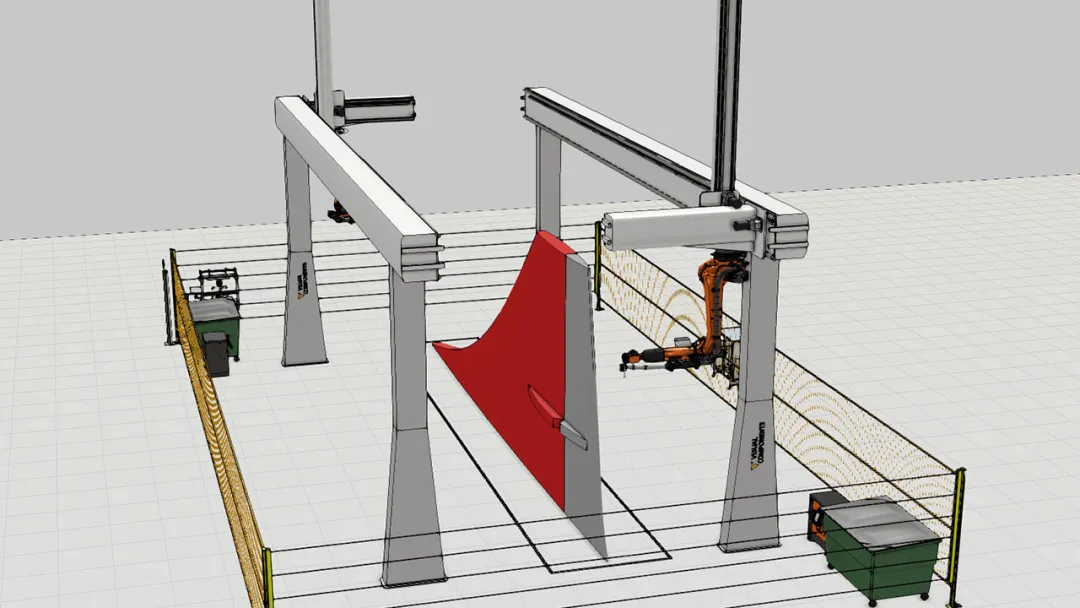

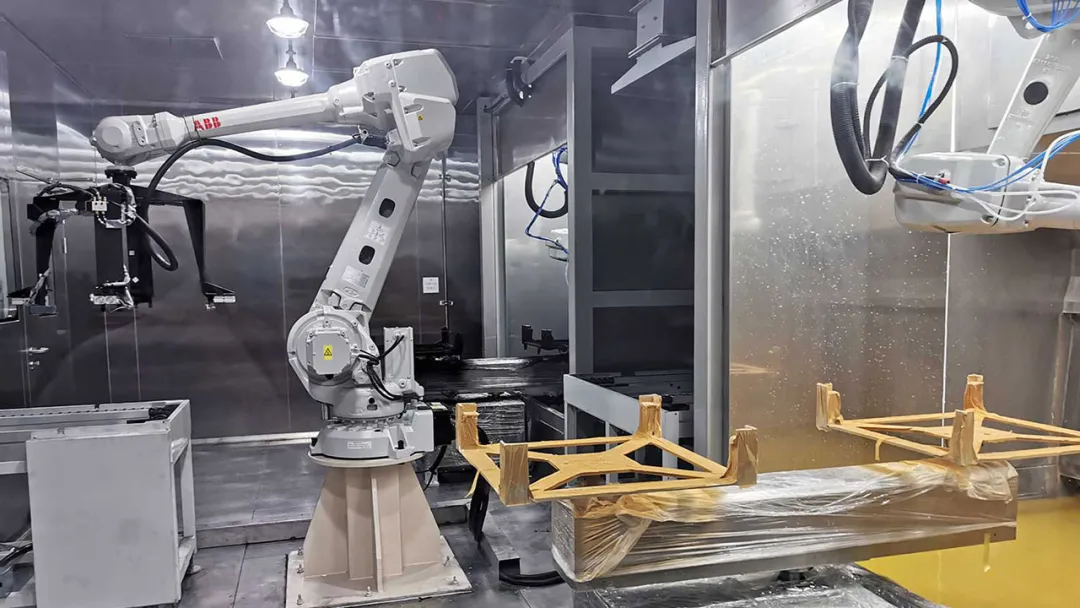

Обладая глубокими знаниями в области процессов точного аэрокосмического производства, мы имеем ключевые технические возможности в полировке критических компонентов авиадвигателей, поверхностной шлифовке аэрокосмических композитных материалов, интеллектуальной очистке деталей из чугуна/алюминия и прецизионной обработке металлических сварных швов. Мы самостоятельно разработали системы шлифовки с постоянным усилием и плавающей головкой, интеллектуальное оборудование для полировки абразивными лентами и устройства для автоматической смены инструмента, сформировав комплексную систему интеллектуального оборудования, охватывающую весь технологический процесс. Мы также развили отличительные технические преимущества в таких областях, как обработка аэрокосмических композитных материалов и окраска обшивки самолетов.

Избранные классические примеры проектов

Шлифовка, нанесение покрытий, инспекция, укладка волокна, взрывозащита и многое другое.

Интеллектуальный гибкий робот для шлифовки и полировки авиационных лопаток

Оборудование для полировки моноколес (Blisk) авиадвигателей

Проект по 8-осевой синхронизированной роботизированной намотке углеродного волокна

Нанесение покрытий на крылья и хвостовое оперение самолетов

Окраска световодных панелей авиационных компонентов

Взрывозащищенный робот, имитирующий дозаправку самолета в воздухе

Команда CNGBS Aerospace Robotics обслуживает аэрокосмические технологические компании, такие как Корпорация аэрокосмической науки и промышленности Китая (Aerospace Science and Industry Corporation, ASIC) и Авиационная промышленная корпорация Китая (Aviation Industry Corporation of China, AVIC), а также предоставляет интеллектуальные решения для предприятий и учреждений, включая Baosight Software, Тунцзийский университет, Шанхайский научно-исследовательский институт стеклопластиков и Хуачжунский университет науки и технологий, непрерывно стимулируя технологическое обновление в области интеллектуального производства аэрокосмической отрасли.