- CNGBS B2B

- 公司介绍、新闻动态、展会活动等信息

- 工博士网

- 工博士-智能制造供应链、FA工厂自动化、MRO工业品一站式采购平台

This case study utilizes welding robots integrated with CNGBS robot positioners and a torch cleaning station to achieve automated welding of electrical control cabinet enclosures, thereby enhancing production efficiency.

Application Scenario

Welding, often termed the industrial "tailor," is a crucial processing method in industrial production and a key link in intelligent manufacturing technology.

Due to the specific nature of the welding industry, the welding process generates significant smoke, arc light, and metal spatter, creating a very harsh working environment. Low production capacity, difficulties in recruiting workers, and thin profit margins have become major pain points hindering development in the welding sector.

Integrating robots with peripheral supporting equipment to form CNGBS's intelligent manufacturing solutions for the welding field can effectively address these challenges.

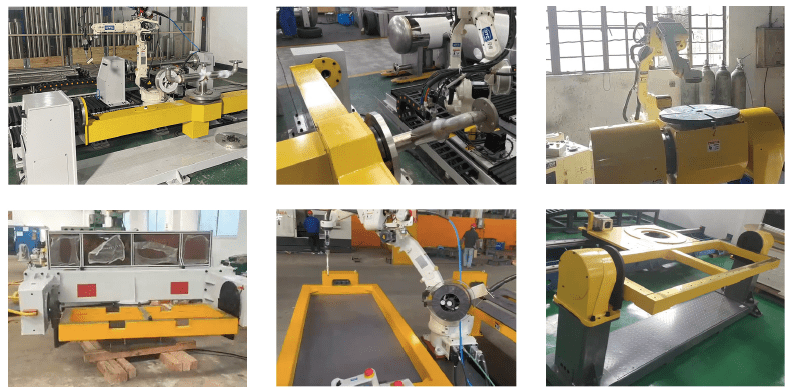

Welding Workstation

The solution employs an OTC welding robot as the core, with CNGBS robot positioners and a torch cleaning station serving as the main supporting equipment, collectively forming an automated welding workstation.

The positioner used is a CNGBS single-axis H-type positioner with an 800 kg load capacity. Placed on both sides of the robot, it creates a dual-station welding setup.

The robot positioner changes the orientation of the product through rotational movement, allowing the robot to achieve an ideal processing position and working speed. The dual-station setup saves the customer time in workpiece clamping and unclamping.

To support the efficient operation of the welding robot, it is essential to equip it with a torch cleaning station for cleaning and maintenance.

The CNGBS robot torch cleaning station ensures that the welding torch does not experience wire clogging during the workstation's operation. The cleaning process is automated, requiring no manual intervention.The application of the welding workstation not only improves production efficiency and ensures welding quality but also allows operators to work away from the harsh environment associated with traditional welding.

By adopting the CNGBS automated welding workstation, the customer has successfully transitioned from manual welding to robotic automated welding, infusing new developmental momentum into their production line.

CNGBS Group continuously advances the development of its own domestic brand product lines, building a proprietary brand portfolio focused on industrial robots, collaborative robots, robot positioners, and other peripheral equipment.

The company remains deeply committed to the fields of robotics, artificial intelligence, industrial automation equipment, and smart manufacturing. Through solid research, development, and innovation, CNGBS aids in the automation and intellectualization of the manufacturing sector. Rooted in China, it aims to empower global manufacturing innovation with "Intelligent Manufacturing in China," and strives to establish "CNGBS" as a central pillar of the "Intelligent Manufacturing in China" brand.

Inquiry Hotline

+86 021-31666777

Service Hotline

Follow us on WeChat

Scan to Follow

Scan to Follow