Интегрирует систему плавающей шлифовки с постоянным усилием и технологию интеллектуального управления силой для адаптивной обработки сложных поверхностей, таких как авиационные лопатки и моноколеса двигателей.

Оснащен функциями автоматической смены инструмента/наждачной бумаги и компенсирует ошибки траектории для повышения выхода годных изделий. Поддерживает шлифовку композитных материалов и удаление заусенцев с металла.

Использует коллаборативные манипуляторы (грузоподъемность 5-20 кг), глубоко интегрированные со станками, поддерживает подачу с поддонов, из магазинов и мобильную многомодовую подачу.

Характеризуется высокой повторяемой точностью позиционирования и совместим с токарными, фрезерными и шлифовальными станками.

Модульная конструкция (серии A/B/C/D) позволяет быстро переналаживаться для мелкосерийного, многономенклатурного производства, значительно повышая эффективность переналадки.

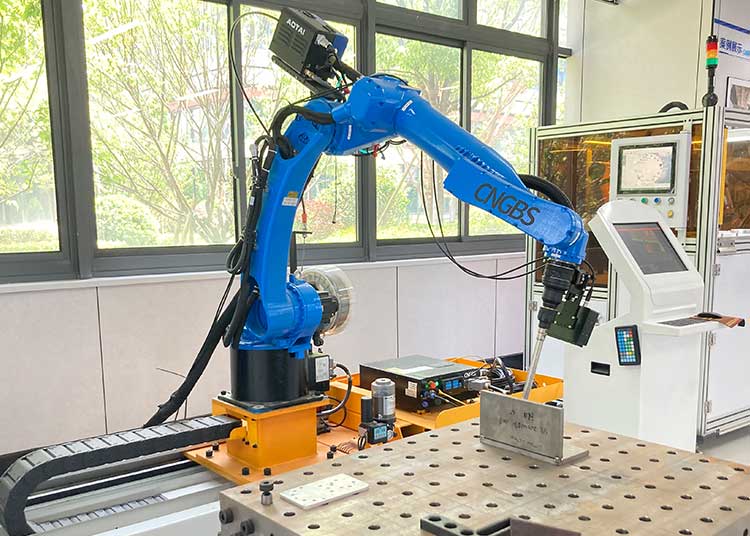

Этот центр использует промышленного робота, установленного на линейную направляющую, для гибкой многостаночной работы.

Обычно применяется для автоматического обслуживания деталей автомобилей, фрезерования крупных аэрокосмических компонентов, автономной замены контейнеров для металлообработки и ремонта крупных заготовок.

Специально разработан для таких отраслей, как аэрокосмическая и автомобильная промышленность, интегрирует взрывозащищенного робота с точной системой подачи краски.

Имеет функции автоматической очистки, смены цвета и смешивания краски в заданной пропорции. Соответствует строгим требованиям к окраске деталей, таких как рамки крыльев самолетов, решая проблемы равномерности покрытия и обработки ЛОС.

Автоматически генерирует сварочные траектории на основе алгоритмов экспертной сварки, устраняя необходимость ручного программирования.

Способна идентифицировать стальные конструкции, такие как коробчатые колонны и двери судовых кают. Оптимизирует процессы с помощью извлечения швов на основе моделей и поисково-позиционирующих действий, сокращая время отладки и адаптируясь к сложным условиям работы, таким как рамные основания прессов.

Горячая линия для запросов

+86 021-31666777

Горячая линия обслуживания

Подпишитесь на нас в WeChat

Сканируйте, чтобы подписаться

Сканируйте, чтобы подписаться